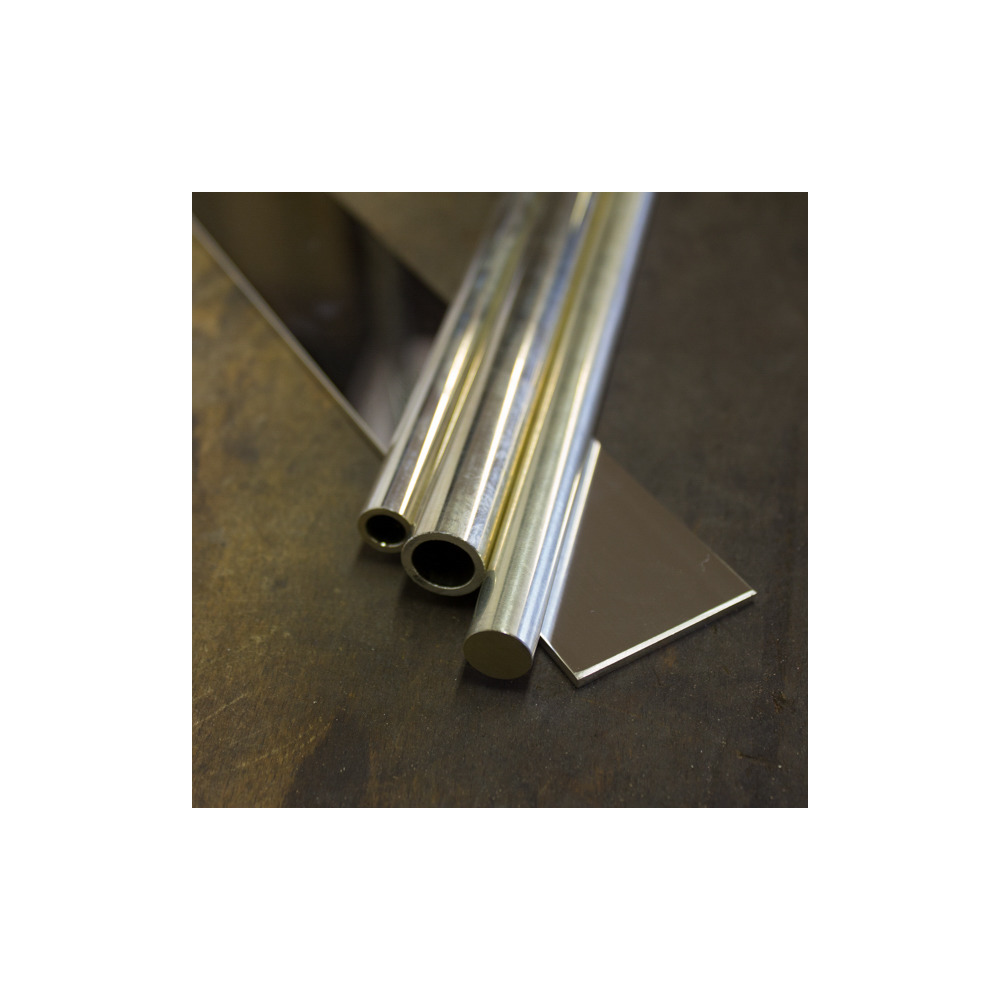

Fabrication

Nowadays, the vast majority of flutes are made industrially, each worker doing a single task in the production line. Our handmade craftsman approach is comparable to stringed instrument makers: we craft our instruments one by one and each of us at Parmenon is able to execute every task one requires, from the initial roughs to the final finishing touches, from machining the components to shaping the embouchure hole.